Research

Learn more about our research highlights, picture of the month, funded projects, and see our list of publications.

Do Intensified Processes Offer the Ideal Space for Performing

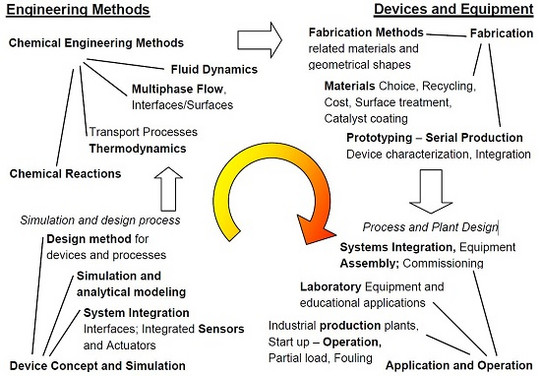

The Laboratory of Equipment Design "Apparatedesign" consists of highly motivated scientific and technical employees, who build the bridge from molecular transformations to equipment implementation in intensified chemical and biological processes. The interplay of convection, diffusion, and (bio-) chemical transformation on the nanoscale and microscale is investigated in single-phase and multi-phase systems. Experimental investigations on coupled reaction and diffusion processes support numerical simulations and physical modeling for the design, fabrication, and operation of successful microstructured components. The entire range of engineering methods as well as their application to the design, manufacture and operation of components and complete systems, is shown in the following figure.

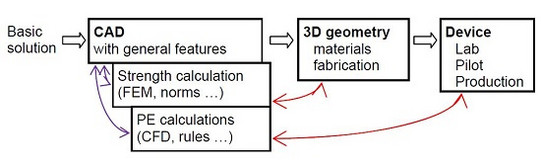

The new findings are to be implemented in a design methodology of modular and compact devices using related fields such as bionics or biomimetics. A device space is offered to intensified transport processes. The design process is supported by Computer-Aided Engineering (CAE) methods, as shown in the following figure.

Current research activities include controlling and utilizing multiphase flows with coupled transport and conversion processes in microchannels. The newly designed devices are suitable for the targeted production of small particles with a narrow size distribution, foams, or colloids from laboratory to production scale. Other applications include phase transfer catalysis or controlled exothermic single-phase, gas-liquid, and liquid-liquid reactions. Integrated measuring and control technology, which collects relevant data close to the process, is important for the design of the device and the successful operation. Various sensors near the wall are investigated for the control of complex systems, which quantify surface processes in microchannels using optical devices and UV/Vis spectroscopy. Own competencies are supplemented by cooperation with other research groups at the TU Dortmund, the IVAM, but also with working groups at other universities and research institutes.

Future research activities

Further research areas are envisioned in the Laboratory of Equipment Design:

Complex transport processes in process engineering devices:

- Fouling in heat and mass transfer processes, basic understanding and mitigation

- Fluid dynamics, heat and mass transfer in the transition from laminar to turbulent flow, improvement of heat and mass transfer in single-phase or multi-phase systems through better understanding of improved flow guidance or targeted surface design

- Unsteady flow and transport processes with guided exploitation and integration into process engineering devices

- Formation of emulsions in microchannels by jet decay and dispersed flow

- Heat transfer in microstructures for convective cooling of surfaces with high thermal load

- Process intensification in reaction engineering in microstructured devices and surface modification, e.g. in areas of catalysis or surface fouling

- Parametric sensitivity of highly exothermic reactions in microchannels

- Process intensification in thermal process technology by integration of microstructures during extraction, distillation and crystallization, as well as membrane processes or thermal diffusion

Alternative methods for the energy input into process engineering apparatus:

- Microwaves: thermal energy to accelerate processes in continuous-flow processes

- Ultrasonic: mechanical energy to produce high local energy densities and dispersion

- Electric fields: for the amplification and control of chemical reactions

- Light and UV radiation: to initiate chemical reactions

These methods have already been successfully applied on the laboratory scale. However, implementation on an industrial scale for production purposes has not yet taken place. Concepts will be developed that allow a successful scale-up of these methods.

Design methodology for process intensification, such as high-performance heat exchangers and microreactors as an iterative process with structural and functional elements, transport processes, production processes, and simulation.

- Use of conventional methods for cost-effective fabrication of microstructures and targeted use of small dimensions in equaling up

- Modular plant and equipment technology for cost-effective and flexible production concepts

Two working principles are important: "Only as small as useful for application, not as small as possible!" and "To achieve the highest possible integration of micro into macro!" to the benefit of the respective applications. This is done in collaboration with other working groups, institutes, and chairs at the TU Dortmund, with Bayer AG and other industrial partners, and with national and international cooperation partners. This has resulted in an active network for investigating complex transport processes and kinetics and the successful further development and application of microstructured devices.