Febuary 2022

- Picture of the Month

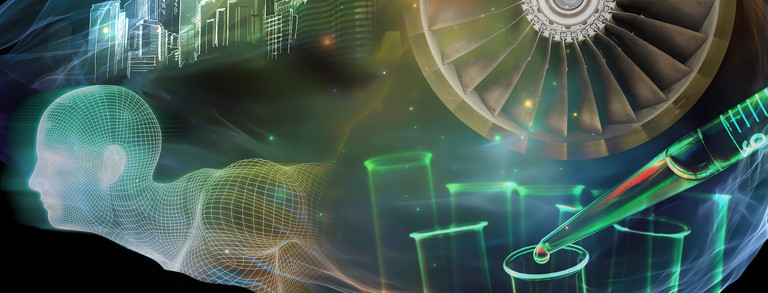

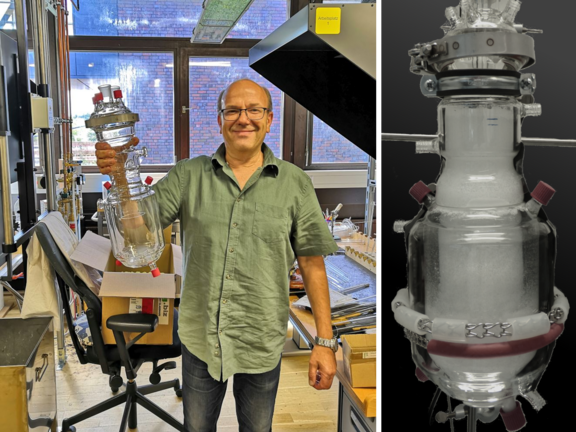

We thank the workshop of the TU Dortmund for glassblowing a draft tube baffle (DTB) crystallizer

Industrial draft tube baffle (DTB) crystallizers are well known and can be found in many applications; however, DTBs are rarely investigated on the laboratory scale. A miniaturized DTB for continuous cooling crystallization with integrated fine-grain dissolution was designed, set up, and characterized. A typical DTB from the m3-scale was scaled down to 2 L filling volume to enable lab-scale investigations concerning process development. The fluid dynamic behavior was determined with suspension performance and residence time of the liquid and solid phase. Five different start-up variations were investigated for cooling crystallization of l-alanine dissolved in water. Hurdles with the periphery were identified, different start-up variations were tested, and the promising ones were determined. It was found that the residence time of the solid phase is shorter than the liquid phase due to the classifying behavior of the DTB, i.e., the crystal residence time could be shortened by decreasing the stirrer speed. The investigations show the potential of the miniaturized DTB for the process development of continuous procedure and small-scale production.

However, for continuous crystallization, there are some hurdles, too, regarding suspension handling. Therefore, to overcome clogging issues concerning the product discharge, due to the smaller dimensions of a continuous DTB crystallizer, a particle screw for supportive suspension discharge was developed and has been described. The presented particle screw showed negligible abrasion effects to the conveyed crystals. The investigations showed that the residence time of different particle sizes depends on the particle screw speed. Additionally, the continuous cooling crystallization experiments with 15 g min−1 confirm the supporting character of the suspension discharge by the particle screw. Thus, the newly developed particle screw for a supportive suspension discharge is well suited for continuous small scale crystallization.

We thank the workshop of the TU Dortmund for glassblowing, especially to Thomas Blöß (left picture); without such research would not have been possible.