ENPRO: REUNION

Energy Efficiency and Process Intensification for the Chemical Industry - Networked demonstrator cluster for optimized process chains

The REUNION project is part of the overall ENPRO project. As a collaboration between academia and companies, ENPRO paves the way for a faster transfer of more flexible, energy-efficient processes into industrial production. Key elements here are the implementation of batch-to-conti at module level, the creation of intelligent and networked modules from the apparatus through to automation and the development of methods and standards for data integration.

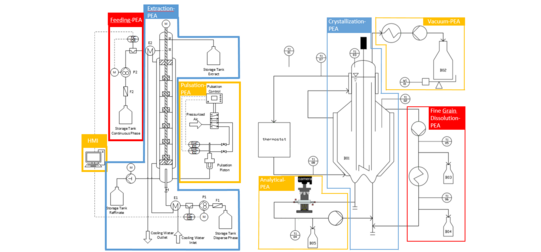

The REUNION (VeRnetzter DEmonstrator-VerbUNd für optimierte PrOzessketteN) sub-project focuses on implementation in the form of demonstrators in the laboratory and in production as well as clarification of the associated challenges. This involves both new plants and the modification, modernisation and expansion of existing plants.

In this context, the equipment design group works on automated, process-intensified stirred-pulsed extraction, agitated mini-reactors and (draft tube baffle) DTB crystallizers. These serve as modules for reaction and separation processes in modular plants.

Information on the project

Contact

Prof. Dr. Norbert Kockmann

Professorship

Laboratory of Equipment Design (AD/BCI)

Funding

Bundesministerium für Wirtschaft und Energie (BMWi), Projektträger Jülich (PTJ)

Partner

NETZSCH Pumpen und Systeme gmbH, Waldkraiburg

HiTec Zang GmbH, Herzogenrath

HNP Mikrosysteme GmbH, Schwerin

Industrial Science GmbH, Darmstadt

KROHNE Innovation GmbH, Duisburg

KSB SE & Co. KGaA, Franke

PFAUDLER NORMAG SYSTEMS GmbH, Hofheim am Taunus

Semodia GmbH, Radebeul

TU Dresden

TU Darmstadt

Associated partners

De Dietrich Process Systems GmbH, Mainz

Evonik Operations GmbH, Essen

Hessisches Ministerium für Umwelt, Klimaschutz, Landwirtschaft und Verbraucherschutz, Wiesbaden

Merck KGaA, Darmstadt

Regierungspräsidium Darmstadt

X-Visual Technologies GmbH, Berlin

Ing. Punzenberger COPA-DATA GmbH

Term

from 01.01.2024 to 31.12.2026